Cable tray systems - efficient management and installation

In modern infrastructure projects, managing and organizing cables efficiently is critical. Cable tray systems offer a robust solution for installing and maintaining cables in various settings, from industrial setups to commercial buildings. Order cable tray systems here to optimize your cable management and ensure safety and efficiency in your electrical setups. This article will guide you through the types, benefits, and applications of cable tray systems, ensuring you make informed decisions for your project needs.

What are cable tray systems?

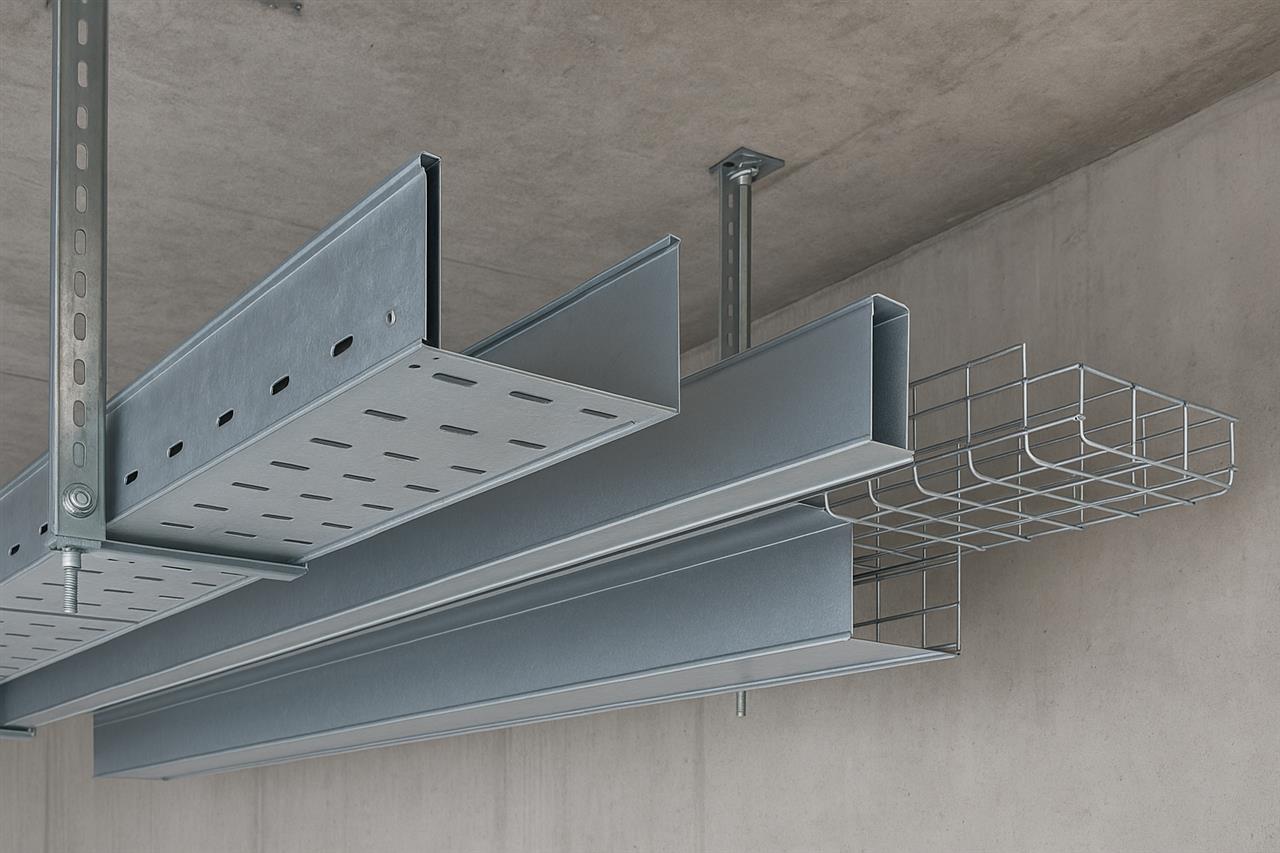

Cable tray systems are structural components used to securely hold and organize power and communication cables within a building or facility. They provide a path for electrical wires and ensure that cables remain organized, accessible, and safe from external elements and mechanical stress. Typically made from materials like steel, aluminum, or fiberglass, cable trays offer a range of designs to fit particular setups and requirements.

Types of cable tray systems

Ladder trays

Ladder trays are the most popular type of cable trays, consisting of two side rails connected by cross bars or rungs resembling a ladder. This design allows easy accessibility for cable installation, maintenance, and heat dissipation. Ladder trays are ideal for handling heavy cable loads and supporting most telecommunication and electrical wiring projects.

Solid bottom trays

Solid bottom trays, also known as channel trays, feature a flat surface without any perforations. They offer great protection against electromagnetic interference and environmental contaminants. These trays are typically used for highly sensitive or hazardous cables in facilities requiring extra protection.

Perforated trays

Perforated trays resemble solid bottom trays but feature small holes or slots on the surface. These perforations improve ventilation and heat dissipation for the cables, reducing the risk of overheating. Perforated trays are highly versatile and are commonly used in light cable installations where heat is a concern.

Wire mesh trays

Wire mesh trays, also known as basket trays, consist of a series of open-mesh structures. Their grid-like design offers excellent flexibility and easy cable installation, modification, and maintenance. Wire mesh trays are typically preferred in data centers or where cables need to be frequently moved or updated.

Benefits of cable tray systems

Improved safety

Cable tray systems significantly reduce the risk of electrical hazards by organizing and securing cables, preventing tripping and reducing the risk of electrical fires. Their robust construction protects cables from mechanical damage, ensuring long-lasting performance and infrastructure safety.

Cost-efficiency

Using cable trays can be more cost-effective than other wiring systems. They reduce the need for complex runs of conduits and boxes, cutting down on material costs and installation time. Simplicity in modification and upgrades also results in lower labor and maintenance expenses over time.

Flexibility and scalability

Cable tray systems are remarkably flexible, allowing for easy changes in cable routing and expansion of the network without replacing the entire system. This adaptability is crucial for growing businesses or infrastructures that anticipate future expansion. Cable trays can be adjusted or added onto, accommodating evolving technological needs efficiently.

Applications of cable tray systems

Cable tray systems are utilized across various industries and applications due to their versatility and reliability. In commercial buildings, industrial plants, data centers, and manufacturing facilities, they play a crucial role in managing electrical, telecommunications, and control wiring systems.

Commercial buildings

In commercial environments such as office buildings, cable trays are used to maintain the organization of communication and power cables, ensuring easy access for maintenance or upgrades without disrupting operations.

Industrial facilities

In factories and plants, heavy-duty cable trays support the robust power and control wiring required for machinery and equipment operations. Cable trays are essential for managing complex wiring systems and maintaining safety and efficiency in industrial settings.

Data centers

Data centers house vast amounts of networking and server equipment, requiring meticulous cable management for optimal operation and cooling. Wire mesh trays are particularly effective here, as they facilitate easy installation, modification, and airflow, crucial for data center efficiency.

Conclusion

Cable tray systems offer a practical, flexible, and cost-effective solution for managing complex cable installations across numerous applications. Whether planning a new building infrastructure or upgrading an existing system, understanding the types, benefits, and applications of cable trays will ensure the success and safety of your project. Make informed decisions and choose the right cable tray system to meet your needs. For your next project requiring reliable and efficient cable management, remember to order cable tray systems here.